|

|

Laser Cutting Machine classification |

Laser Cutting Machine classification

A Laser

a1 Solid Laser

a2 Semiconductor Laser

a3 Liquid Laser

a4 Gas Laser

B Laser Cutting Machine Structure

b1 Desk Type Laser Cutting Machine

b2 Gantry Type Laser Cutting Machine

C Cutting Material

c1 Metal

c2 No Metal

c3 Tube |

| 2012-07-04 |

|

|

|

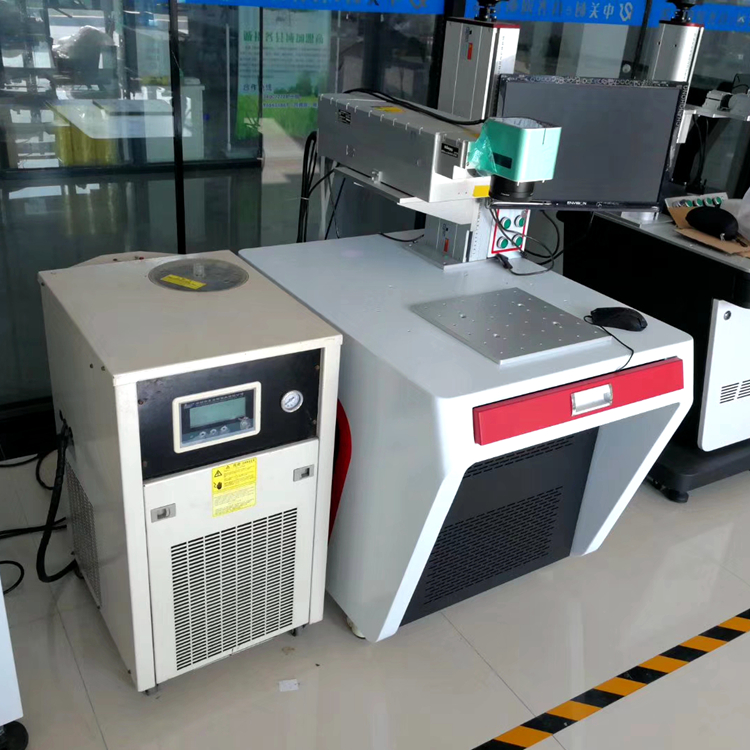

Fiber Laser Marking Machine Usage |

Fiber Laser Marking Machine Usage

In the industry field, fiber laser marking machine are widely used in integrated circuit chips, computer accessories, industrial bearings, watches, electronic and communications products, aerospace components, various automotive parts, home appliances, hardware tools, molds, wire and cable, food Labels for graphics and text in many fields such as packaging, jewelry, tobacco, and military, as well as mass production line operation.

In function field, fiber laser marking machine can achieve:

1. Alumina is cracked to be black color. There is MOPA technology fiber laser marking machine with adjustable pulse width.

2 Mark color on metal. User has to adjust and try some parameters according to the material.

3. The metal is cracked to be black color. It is similar with the second point;

4. On-line fly marking work. It means that the fiber laser marking machine is combined with the assembly line to mark when feeding.

5, Portable fiber laser marking machine. It is small and no occupy the place which can meet the basic marking requirement.

In material field, the fiber laser marking machine is used for rigid, brittle, dark material and most of the metal materials, as well as certain non-metallic materials such as plastics, fiber laser marking machines can mark. Marking effect is based on actual results.

|

| 2012-07-05 |

|

|

|

Why choose Fiber Laser Cutting Machine for sheet metal? |

After the revision of the site, the application of the advanced web development program and design concept, the blue for the tone of the layout and website content than ever, clarity, so that customers more quickly according to their own needs to browse the web. In order to better Introduction Company, to help customers to understand the correct and comprehensive division, we add a company profile, product demonstration, case shows and other columns, the website to add more comprehensive column content, in order to better serve the majority of customers, and deepen exchanges with the industry. |

| 2010-08-04 |

|

|

|

UV Laser Marking Machine Introduction |

Ultraviolet laser marking machine belongs to the series of laser marking machines, but it is developed with a 355nm ultraviolet laser, which uses third-order cavity frequency doubling technology.

Compared with the infrared laser, the 355 ultraviolet light spot is extremely small, which can greatly reduce the mechanical deformation of the material and the processing heat effect is small, because it is mainly used for ultra-fine marking and engraving, and is particularly suitable for food and pharmaceutical packaging materials Applications such as marking, micro-hole drilling, high-speed division of glass materials, and complex graphic cutting of silicon wafers. |

| 2020-07-08 |

|

|

|

Pulsed laser cleaning machine advantage |

Pulsed laser cleaning machine is a high-tech product for surface cleaning. Easy to install and control.

Simple operation. After opening the machine, it can achieve cleaning without chemical reagent, no medium, no dust, no water.

Auto focus, surface cleaning, high surface cleanliness, and can remove the resin,oil, stains, dirt, rust, coating, plating, paint. on the surface of the object. |

| 2018-09-29 |

|

|

|

Fiber Laser Cleaning Machine for rust removal |

Laser cleaning machine is also called laser rust remover. Its principle is mainly based on the absorption of laser energy by pollutants on the surface of the object, or vaporization, or instantaneous thermal expansion to avoid the surface of the particles onto the adsorption force, to make it off the surface of the object. Then it achieve the purpose of cleaning.

It uses the laser to act on the work piece, without using any chemicals and syrups. No need to be in direct contact with the work piece. |

| 2012-07-08 |

|

|

|